Important Concepts:

The charge controller stops charging of the batteries when they’re full, preventing damage to them.

Most charge controllers will be destroyed if you hook up too many solar panels to them, so you need to read the spec sheets and make sure your system will never supply too many amps or too high a voltage to the charge controller.

There are two common types of charge controllers: PWM (Pulse Width Modulated) and MPPT (Maximum Power Point Tracking)

Types of controllers

PWM controllers are used in small systems due to their much lower cost. You need to pick one that matches your battery voltage (usually 12 V) but you also need to pick solar panels that are designed for your battery voltage. They are a little less efficient than MPPT controllers, but for small systems the cost of using a slightly larger solar panel is typically much less than the cost of upgrading to a MPPT controller.

PWM controllers are used in small systems due to their much lower cost. You need to pick one that matches your battery voltage (usually 12 V) but you also need to pick solar panels that are designed for your battery voltage. They are a little less efficient than MPPT controllers, but for small systems the cost of using a slightly larger solar panel is typically much less than the cost of upgrading to a MPPT controller.

MPPT charge controllers are more expensive and more efficient because they run your panels  at whatever voltage that produces the most power at the moment. The improvement is small, typically gaining 15% to 20% when the sun is low, and almost no improvement when the sun is high in the sky. Perhaps more importantly, they allow you to hook up solar panels in series providing a higher voltage than your batteries. This means you can run fewer smaller wires up to your roof and still have very low resistive losses in the cables because you are running higher voltage at lower amperages (that is, the rate of electron current flow measured in the unit of amperes) and losses are proportional to amperage squared. MPPT controllers are used in medium and large systems since their higher cost is offset by increased efficiency and lower costs for the panels and copper wiring.

at whatever voltage that produces the most power at the moment. The improvement is small, typically gaining 15% to 20% when the sun is low, and almost no improvement when the sun is high in the sky. Perhaps more importantly, they allow you to hook up solar panels in series providing a higher voltage than your batteries. This means you can run fewer smaller wires up to your roof and still have very low resistive losses in the cables because you are running higher voltage at lower amperages (that is, the rate of electron current flow measured in the unit of amperes) and losses are proportional to amperage squared. MPPT controllers are used in medium and large systems since their higher cost is offset by increased efficiency and lower costs for the panels and copper wiring.

Design Considerations

Amperage

Controllers are rated by the amps they can safely pass. Divide the wattage of the panels by the voltage of the battery bank to determine approximately how many amps the charge controller needs to handle. (Applies to both PWM and MPPT controllers) This is usually conservative because in most locations the solar panels will put out fewer watts than their rating. However, if you live in a location that is sometimes both clear and cold, your solar panels could actually exceed their wattage rating on some days. If your calculated amperage is close to the amperage rating of you controller, be careful. Some charge controllers will shutdown to protect themselves, but others will simply pass all the current and burn out. Read the spec sheet.

Controllers are rated by the amps they can safely pass. Divide the wattage of the panels by the voltage of the battery bank to determine approximately how many amps the charge controller needs to handle. (Applies to both PWM and MPPT controllers) This is usually conservative because in most locations the solar panels will put out fewer watts than their rating. However, if you live in a location that is sometimes both clear and cold, your solar panels could actually exceed their wattage rating on some days. If your calculated amperage is close to the amperage rating of you controller, be careful. Some charge controllers will shutdown to protect themselves, but others will simply pass all the current and burn out. Read the spec sheet.

Maximum Voltage

A MPPT controller allows the panels to be connected in series for a much higher voltage than the battery bank, however, you need to check the maximum voltage rating of the controller against the corrected Voc of your panels in series on the coldest day they might experience (e.g. the record low temperature ever). Voc isn’t a constant, but it varies with temperature, going up with colder temperatures. Using the solar panel datasheet you can calculate your corrected Voc for your record low temperature. Make sure your string of solar panels won’t exceed the MPPT controller’s maximum voltage rating.

Outback Power has a handy string sizing tool that does the math for you showing how many panels you can safely configure in various series-parallel configurations without exceeding any of the charge controller limitations. http://www.outbackpower.com/resources/technical-support/string-sizing-tool

Environmental Considerations

Can your charge controller withstand the weather it will be subjected to? Will it be outdoors or exposed to salt air? Will it overheat inside a closed box in a hot room? Check the ratings. Most need free airflow to cool them. Running the charge controller in a hot poorly ventilated area (like a closed cabinet) will shorten its lifetime because heat is bad for the components. Conversely, it you’re running at amperages well under its maximum rating, it will tend to run cool and last longer.

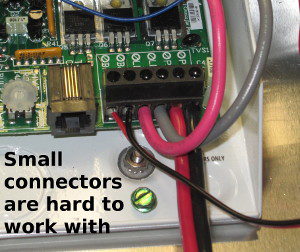

Wiring considerations

Heavy wires are needed for 12 V systems to minimize losses. Are the terminals on the controller large enough to handle the heavy wires you plan on using? Small terminal strips soldered directly to a circuit board can be broken off by stiff wires. Consider how you will mount and connect to your charge controller.

Built-in Electronic protections

Of course you would never make any mistakes, but somebody else maintaining your system might. Does the charge controller have reverse polarity protection, electronic short circuit protection, overload and overheat protection? They may save you a lot of down-time, trouble and expense.

Recommendations

Our charge controller category lists some of the charge controllers we are confident in recommending and sell often, but there are many others on the market.